INDOOR AIR QUALITY: A MAJOR ISSUE

We spend most of our time inside buildings. The air we breathe has a direct impact on our quality of life and our health, especially amongst vulnerable populations, such as children and elderly people.

Healthy air prevents chronic diseases from developing.

Consequently, the products used for construction and decoration must be clearly and legibly labeled with details of their volatile organic compound (VOC)* emissions in order to control the quality of indoor air.

Emissions from products are ranked from A+ (very low) to C (high), according to the same principle that is used for household appliances and vehicles. Plafometal’s metal ceilings solutions, with or without an acoustic fleece on the back of the panels, belong to the top health category (A+).

*The values shown might change depending on additional tests. Users are responsible for checking the current values before using the product.

INDOOR AIR QUALITY WITH PLAFOMETAL

Emission tests are made according to the following standards:

- ISO 16000-9 (emission test chambers) with formaldehyde analysis according to ISO 16000-3

- ISO 16000-6 VOCs (volatile organic compounds)

Plafometal’s ceilings are tested in order to meet the standard EN 13964, Annex E. They are ranked in the E1 category, which is the best possible category for formaldehyde emissions.

CE MARKING

Our suspended ceilings have the CE marking, which constitutes:

- a passport for their free circulation in the European Union,

- a guarantee of conformity with the requirements of the EN 13964 standard for suspended ceilings.

Since July 1st, 2013, construction products in Europe covered by a harmonized standard, or conforming with their European technical evaluation, must have a Declaration of Performance (DoP). The DoPs of our products can be downloaded from the “Learning Center”.

LIFE CYCLE ANALYSIS (LCA)

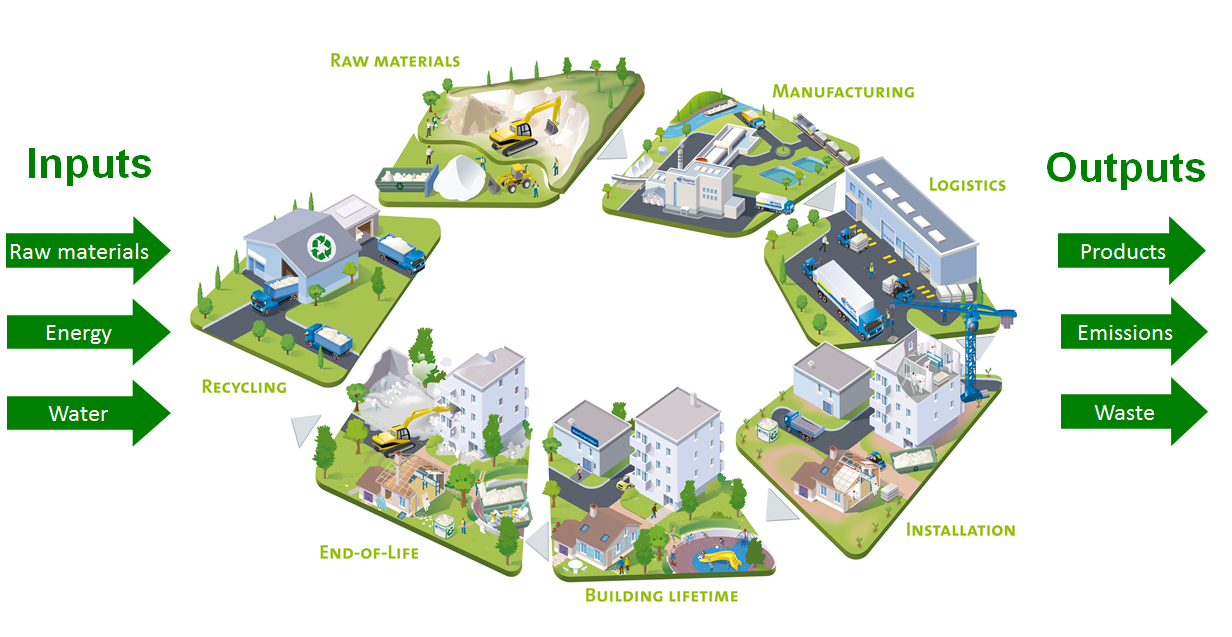

THE LIFE CYCLE OF A BUILDING

The LCA consists of analyzing all the flows of materials, energy, etc., in and out of a building during its life cycle, in order to assess the corresponding environmental impacts.

The LCA objectively quantifies the use of energy and raw materials, emissions into the air, emissions into water and generation of waste.

A product's LCA:

Fiche de Données Environnementales et Sanitaires (FDES)

THE THREE FACTORS CHARACTERIZING AN EHPD

The results of the LCA are summarized in the Environment and Health Product Declaration (EHPD).

- Its functional unit: the unit of reference in an LCA. It expresses the impacts on an element of the building during its typical lifetime. The typical lifetime of a Plafometal product is similar to that of a building (50 years).

Examples of functional units: 1m², 1 kg, etc. - Its scope: cradle to gate OR cradle to grave (chosen by Plafometal).

- The origin of its data: the data is provided by the manufacturer, in which case it is specific to the origin of the product data and is released under the manufacturer’s own responsibility. Or the data is sourced from professional organizations and is based on the average values of the manufacturers in the market.

In France, Environmental Product Declarations / Environment and Health Product Declarations are valid for 5 years.

THE BENEFITS OF AN EHPD

EHPDs offer a number of advantages: they are objective, qualitative and quantitative, and they are presented in a standard format.

EHPDs are intended to help project owners, designers and contractors to:

- choose their materials,

- calculate the environmental impact of their project, on the basis of the EHPD of every product used in the project,

- obtain an environmental certification for the building, given that the EHPD can be used to win points according to every reference system.

THE PLAFOMETAL EHPDS

The EHPDs of Plafometal’s panels have been verified by a third party since 2017.

ENVIRONMENTAL CERTIFICATIONS

Certain regulations and the evolution of the market towards more sustainable buildings have given rise to the development of environmental certifications.

Certifications are not compulsory.

Certification is a voluntary initiative taken by the building’s owner in order to construct a building that is more environmentally friendly and protects the health of the occupants.

Important: these certifications cover buildings only, not products.

The most widespread certifications are BREEAM® (UK), LEED® (US/Canada), NF HQE™ (France), VERDE® (Spain), CASBEE (Japan), DGNB (Germany) and Green Star (Australia).

Three certifications are used in France: NF HQE™, BREEAM® and LEED®.

LEED® (Leadership in Energy and Environmental Design) is a system for the evaluation of the environmental quality of buildings developed by the US Green Building Council in the United States in 1998.

LEED® (Leadership in Energy and Environmental Design) is a system for the evaluation of the environmental quality of buildings developed by the US Green Building Council in the United States in 1998.

The Building Research Establishment Environmental Assessment Method (BREEAM®) is a British certification standard developed by the Building Research Establishment in 1990.

NF HQE™ (Haute Qualité Environnementale) certification is an environmental management system developed by the HQE organization in France in 1997.

Please refer to our environmental brochure for more details of how our Eurocoustic ceilings contribute to the LEED®, BREEAM® and NF HQE™ certifications.

HQE INITIATIVE

Plafometal’s ceilings on the suspended ceilings market meet 11 of the 14 targets of the French “Haute Qualité Environnementale” initiative.

HARMONIOUS RELATIONS

We focus on the freedom offered by shapes that can be adapted to the imperatives of projects and architectures.

PROCESSES AND PRODUCTS

We offer products that are 100% recyclable indefinitely. As an example, 40% of the steel comes from recycling.

LOW-NUISANCE SITES

Our products are delivered to the right dimensions and pre-cut, ready for the integration of equipment, making them quicker to install and limiting noise pollution. Furthermore, our deconstructed products are clean and recyclable, with nothing going to landfill.

ENERGY MANAGEMENT

The light reflection performance coming from the coatings reduces the need for artificial lighting, while enabling a better use of natural daylight.

CARE AND MAINTENANCE

Our permanent and removable ceilings offer long-term access to the equipment in the plenum, thanks to products such as metal panels, for example. Care is limited to simple cleaning at unlimited frequencies.

THE FOUR TYPES OF COMFORT

- Hygrothermal comfort: When combined with soundproofing absorbents, such as stone wool, our suspended ceilings facilitate the thermal insulation of the ceiling.

- Acoustic comfort: Our acoustic metal ceilings solutions (perforated and filled products) meet the acoustic requirements for absorption and lateral attenuation.

- Visual comfort: The light reflected from the coatings diffuses the daylight and contributes to the distribution of natural light.

- Olfactory comfort: Our materials are odorless and the integration solutions of our ceilings contribute to the efficient operation of the ventilation equipment.

SANITARY QUALITIES AND INDOOR AIR

The coatings are inert and do not favor the development of bacteria and mold. They are easy to clean and maintain.