ACOUSTICS

Acoustic absorption properties are added to metal by perforating the metal ceiling, so that the sound waves can circulate.

Common sense would say that more perforations with a larger diameter would make for better acoustic absorption. But this is not the case. In fact, the number of perforations make little difference to the absorption. Therefore, the choice of the number of perforations is essentially an esthetic one.

Ceilings: an ideal surface The ceiling is usually the largest single free surface in a room, and is the best suited to applying an acoustic treatment. To begin with, it helps to diminish sound reverberations.

ACOUSTIC COMFORT

Metal’s capacity to absorb sound becomes essential when looking for greater acoustic comfort inside a building. A good acoustic ambience makes a space more comfortable, and is also conducive to peace of mind, work and healing processes.

They also contribute to the phonic insulation of adjacent spaces.

ACOUSTIC ABSORPTION

The acoustic absorption of a suspended ceiling corresponds to its capacity to reduce the reflected energy in order to reduce the reverberation time of the sound waves inside a room.

ACOUSTIC ABSORPTION INDEXES

The absorbent capacity of a ceiling is measured by:

the a Sabin coefficient, calculated by frequency bands, as per EN ISO 354,

the weighted sound absorption coefficient αw, as per EN ISO 11654. This unique value simplifies the comparison of absorption performances between solutions.

These coefficients range from 0 (no absorption) to 1 (total absorption).

PLAFOMETAL ACOUSTIC METAL CEILINGS

Plafometal has developed a complete range of metal ceilings to meet all kinds of acoustic needs.

- The ALPHA offer absorbs up to αw = 0.85 (class B), making it much easier for occupants to understand one another. Ideal for passageways.

- The ALPHA PLUS offer guarantees absorption of up to αw = 1, for optimal acoustic comfort.

The ALPHA and ALPHA PLUS offers make offices, classrooms and hospitals much quieter places.

LATERAL ATTENUATION

Lateral attenuation is the capacity of a suspended ceiling to reduce the transmission of sound between adjacent spaces that share the same plenum, a construction method that is common in tertiary sector buildings.

Lateral attenuation indexes

The lateral attenuation of ceilings is measured in laboratories, according to EN ISO 10848-2. It is expressed by:

- the standardized Dn,f,w lateral sound reduction index, expressed in dB

- the standardized Dn,t,w weighted sound reduction index Dn,t,w

A single Dn,f,w index can be calculated and expressed in dB.

THE PERFORMANCE OF ACOUSTIC METAL CEILINGS

The enclosing cover (sheet steel or plasterboard) on the plenum side of the metal panel and our absorption solutions give our metal ceilings excellent lateral attenuation performances: Dn,f,w up to 51 dB.

FIRE PROTECTION

The preventive measures to protect persons against fire are described in the French regulations covering fire protection in buildings. They are intended to protect the emergency services, while also facilitating their operations and protecting the property too.

There are two categories of fire prevention requirements:

- active means of protection, including detectors and sprinkler-type water spraying systems,

- passive means of protection, which include the fire behavior of the construction materials and the fire resistance of the components of the building.

ACTIVE PROTECTIVE MEASURES

Plafometal builds cut-outs into most of its ceilings in the factory, for the perfect integration of equipment, like fire detectors and sprinklers.

The standard covering fixed firefighting systems in perforated suspended ceilings requires a total open surface of at least 70% of the flat surface of the ceiling.

As a general rule, it is agreed that the parts of a metal ceiling (excluding lighting and equipment) must have an open surface representing at least 80%. Our vertical open-cell and linear strip solutions meet this requirement, depending on the dimensions of the cells.

FIRE REACTION

Fire reaction is an intrinsic characteristic of a material that defines its contribution to the development of a fire.

Plafometal’s metal ceilings solutions offer the very best fire reaction performances.

- A1 for all non-painted and non-prepainted products, with or without fleece

- A2-s1, d0 for powder coated or filled products

*The values shown are subject to change further to additional tests. Users are responsible for checking the current values before using the product.

The fire reaction performance of the parts of a suspended ceiling must be classified according to various regulations that are unified on a European scale. They are described in:

- the Euroclasses standard. This new standard followed the publication of the order on November 21, 2002, pertaining to the fire reaction of construction products and interior fittings.

- the product standard EN 13964 describing the requirements and test methods applying to suspended ceilings.

FIRE RESISTANCE

Fire resistance characterizes the time for which the parts of buildings continue to play their role, despite the effects of the fire.

The Plafometal solutions:

1. For France

Fire-resistance performance of SF 1/4 h and SF 1/2 h meeting applicable French fire regulations for shared-use corridors inside high-rise buildings in a reception area.

For all needs: Monobac SF (Clip-in metal tile), PM&SF (self-supporting panels) or ORIAL SF (swing-down panels) in corridors. Installation must conform with the reports and annexes (available on demand) and §5.6 of DTU 58-1, December 2008.

Suspended ceiling regulations in France:

The regulatory requirements for the classification of the fire resistance of suspended ceilings for buildings open to the public are different, depending on whether or not they contribute to the protection of the structural elements of the building.

The use of suspended ceilings as a shield to protect structures required:

- a test, as per ENV 13381-1

- REI-type classification, according to the unified European regulations.

Suspended ceilings that do not protect structural elements against fire must meet other requirements, relating to:

- mechanical resistance to fire, i.e. no falling parts. This requirement, which applies to common horizontal passageways in high-rise buildings, must be tested and requires a fire resistance type classification (SF).

2. For Belgium

Suspended ceiling regulations in Belgium:

The regulatory requirements stipulate that suspended ceilings must be 1/2h fire-resistant. This condition applies to suspended ceilings that must meet the requirements for mechanical fire resistance for evacuation passages, premises accessible to the public and collective kitchens.

We propose metal ceiling solutions with a fire resistance of 1/2h, based on tests by WarringtonFireGent.

Installation must conform with the classification and test reports (available upon request)

LIGHT REFLEXION

With light reflection indexes up to 87% of unperforated versions and up to 79% for perforated versions, Plafometal’s metal ceilings reflect the incident daylight, helping to add more natural light and to reduce needs for artificial lights.

PROTECTION AGAINST CORROSION

INDOOR INSTALLATION

- Products must be installed in accordance with DTU 58-1 code of practice.

- If metal ceiling systems are installed over large surface areas and are subject to high variations in temperature, steps must be taken to address thermal expansion in the materials, such as installing appropriate expansion joints.

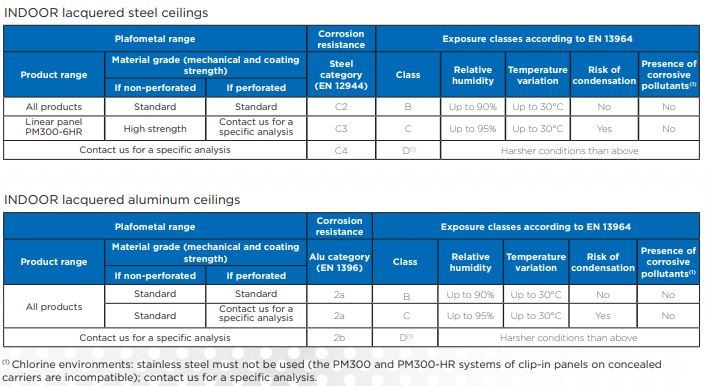

Corrosion protection according to EN 13964:

- Class B (varying relative humidity up to 90%, varying temperature up to 30°C, but without corrosive pollutants): all our solutions made from standard steel.

- Class C (relative humidity up to 95%, varying temperature up to 30°C and accompanied by a risk of condensation, but without corrosive pollutants): all our non-perforated solutions made from standard aluminum and our PM300-6HR system of clip-in panels on concealed carriers made from high-strength steel. In case of perforated panels, contact us for a specific analysis.

- Class D (more severe than the above - chlorine environments): stainless steel must not be used (the PM300 system of clip-in panels on concealed carriers is incompatible); contact us for a specific analysis.

CHEMICAL RESISTANCE TO DISINFECTION PRODUCTS

Our metal ceilings and wall panels have been tested with three types of disinfection chemicals recommended by the World Health Organization against the main viruses, including COVID-19: sodium hypochlorite 2.5%, hydrogen peroxide 6% and ethanol 70%.

Test methods include long or repeated exposures to these chemicals. The results are evaluated according to the standard exposition EN 12720 and the standard disinfection and wet abrasion ISO 11998 (tests carried out with a microfibre cloth).

All metal ceilings are resistant to these three disinfectants. However we recommend some product depending on the use:

- Sodium hypochlorite 2,5%: OK for all ceilings (no visual change)

- Hydrogen peroxide 6%: only black powder-coated ceilings show minor visual change ; no visual change on other ceilings

- Ethanol 70%: only white prepainted and wood finish ceilings show minor visual change ; no visual change on other ceilings

This is valid for all products (steel and aluminum, prepainted and powder coated, with acoustic complement).

Acoustiroc® metal wall panels are resistant to these three disinfectants.

All this information can be found in the "Maintenance" https://www.plafometal.com/product-catalog-appendices