Product Benefits

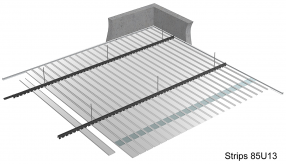

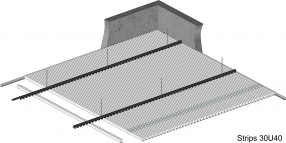

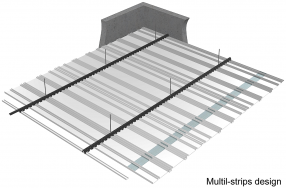

- Aesthetics: reinforced linear appearance and multi-strip design possibilities (combination of different widths and heights)

- Dimensions: different widths and heights available, and long lengths possible

- Installation : easy to fit

Related system :

Linear strip with straight edges on semi-concealed grid system TYPE U [PLAFOMETAL-LC-120]

Caracteristics & Performance

Light reflexion

- Up to 87%.

Fire reaction

According to EN 13501-1 :

- Euroclass A1

Chemical resistance

Our metal ceilings and wall panels have been tested with three types of disinfection chemicals recommended by the World Health Organization against the main viruses, including COVID-19: sodium hypochlorite 2.5%, hydrogen peroxide 6% and ethanol 70%.

Test methods include long or repeated exposures to these chemicals. The results are evaluated according to the standard exposition EN 12720 and the standard disinfection and wet abrasion ISO 11998 (tests carried out with a microfibre cloth).

All metal ceilings are resistant to these three disinfectants. However we recommend some product depending on the use:

- Sodium hypochlorite 2,5%: OK for all ceilings (no visual change)

- Hydrogen peroxide 6%: only black powder-coated ceilings show minor visual change ; no visual change on other ceilings

- Ethanol 70%: only white prepainted and wood finish ceilings show minor visual change ; no visual change on other ceilings

This is valid for all products (steel and aluminum, prepainted and powder coated, with acoustic complement).

Regulations

Environment and health

- Our ceilings can be fully recycled over an indefinite period of time.

- They are sustainable, easy to maintain, produce no dust, particles or vapor, are inert and odor-free.

- They do not promote microbial growth and do not emit any VOCs or formaldehyde.

CE Marking

- DoP No.: @@MARQUAGE_CE@@

Indoor Air Quality

The products are classified A+

Installation & Cleaning

Type of installation

- Framed installation

- Outdoor installation

Installation (preview)

- Installation according to DTU 58.1

- Framed installation : hangers with 1,200 mm centers starting 300 mm from the wall, and carriers with 1,200 mm centers with a 300-mm strip overhang. Perimeter channels recommended.

Outdoor installation

- Outdoor installation: contact us for details about the center spacings for the chosen strip and specify the degree of wind and corrosion exposure depending on the project's installation specifications. The contractor is responsible for submitting its plan to the client for approval. Generally speaking, allow for a 0.5 to 1 m center spacing between hangers and carriers, a rigid tube for every other hanger

at least between the fixing and the carrier, as well as washers on the contact points between the threaded rod and carrier. The gap cover at the bottom should be left out..

Colors & Dimensions

Material

- Aluminum 0.5 or 0.6 mm thick. Steel available. Please contact us.

Colors and finishes

- Standard White ( RAL 9003) - polyester prepainted.

- Metallic Grey (RAL 9006) - polyester prepainted.

- Structured textured White ( RAL 9003) - polyurethane polyamide prepainted.

- Structured textured Grey (RAL 9006) - polyurethane polyamide prepainted.

- Other colors, brushed, anodized and wood imitation on request - refer to the color chart available.

Packaging

Cut outs and integrations

- Performed on site. Specific covers for spotlights, sprinklers or other fittings on one or more strip modules are available on request..

A day-to-day support

At Plafometal, we support our customers on a daily basis through each step of a construction project. Following the whole project, from the building owner’s request to the delivery, we provide our customers with all advice and recommendations they may need.