Product Benefits

- Opening: open interest with panel remaining in the plenum

- Acoustics: high degree of correction, absorption factor αw up to 1

- Installation: adjustable closed hollow joint with a system of offset perimeters in two parts

- Impermeability: closed hollow joint to insulate against equipement noise.

Related system :

Sliding panel system TRANSLABAC [PLAFOMETAL-CC-230]

Caracteristics & Performance

ACOUSTIC ABSORPTION

- αw up to 0.85 with the ALPHA range

- αw up to 1 with the ALPHA PLUS range

Check out our video "Acoustic metal ceilings" in our Learning Center.

Acoustic filling

- ALPHA offer: black acoustic fleece bonded on the back of perforated ceilings.

- ALPHA PLUS offer: two options of acoustic inlays are possible. The surfaced insulating wool for optimal performances or encapsulated insulating wool to avoid fibers.

Acoustic performances of ceilings are guaranteed for products defined, controled and entirely delivered by Plafometal.

Light reflexion

- Up to 87%.

Fire reaction

According to EN 13501-1 :

- Euroclass A1 for the prepainted non-perforated

- Euroclass A1 for the prepainted in the ALPHA range

- Euroclass A2-s1, d0 for non-perforated powder post-painted

- Euroclass A2-s1, d0 for powder post-painted in the ALPHA range

- Euroclass A2-s1, d0 for the product in the ALPHA PLUS range

Chemical resistance

Our metal ceilings and wall panels have been tested with three types of disinfection chemicals recommended by the World Health Organization against the main viruses, including COVID-19: sodium hypochlorite 2.5%, hydrogen peroxide 6% and ethanol 70%.

Test methods include long or repeated exposures to these chemicals. The results are evaluated according to the standard exposition EN 12720 and the standard disinfection and wet abrasion ISO 11998 (tests carried out with a microfibre cloth).

All metal ceilings are resistant to these three disinfectants. However we recommend some product depending on the use:

- Sodium hypochlorite 2,5%: OK for all ceilings (no visual change)

- Hydrogen peroxide 6%: only black powder-coated ceilings show minor visual change ; no visual change on other ceilings

- Ethanol 70%: only white prepainted and wood finish ceilings show minor visual change ; no visual change on other ceilings

This is valid for all products (steel and aluminum, prepainted and powder coated, with acoustic complement).

Regulations

Environment and health

- Our ceilings can be fully recycled over an indefinite period of time.

- They are sustainable, easy to maintain, produce no dust, particles or vapor, are inert and odor-free.

- They do not promote microbial growth and do not emit any VOCs or formaldehyde.

CE Marking

- DoP No.: @@MARQUAGE_CE@@

Indoor Air Quality

The products are classified:

- A+ for all the products non-perforated

- A+ for all the products in the ALPHA range

- A+ for all the products in the ALPHA PLUS range, with a specific mineral wool pad in this plastic film

- A for all the products in the ALPHA PLUS range, with a specific mineral wool pad with black tissue face

Installation & Cleaning

Type of installation

- Installation in corridor

Installation (preview)

- Installation according to DTU 58.1

- Installation in corridor: Translabac wall angles t be fixed to the wall every 300 mm and Translabac hinged orofiles to be assembled with bolts (not supplied) beneath the wall angle every 300 mm.

Disassembling for access to the plenum

- The panel is opened by pushing it upwards and then sliding it and setting it down on the top wings of the perimeter profile.

The panel then slides into the plenum above the panels still in place. The panel is repositioned in reverse order.

Colors & Dimensions

Material

- Galvanized steel from 0.6 to 0.8 mm thick depending on the width and length.

Colors and finishes

- White 137 (~ RAL 9003) - polyester prepainted.

- Metallic Grey (RAL 9006) available on request - polyester prepainted.

- 180 RAL colors available on request - polyester powder coating.

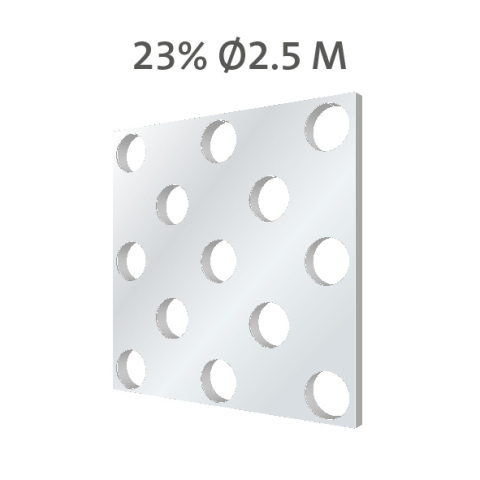

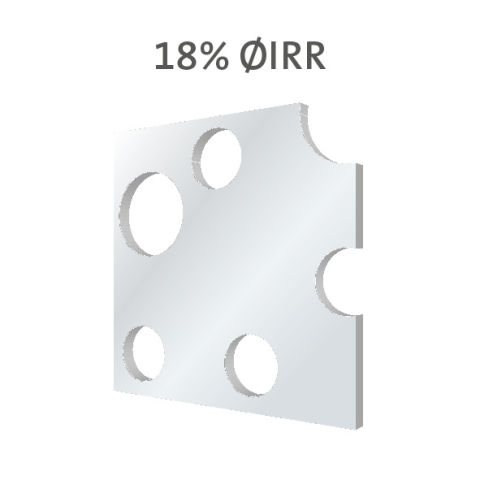

Perforations on steel

- Plain

- 11% Ø1.5 M

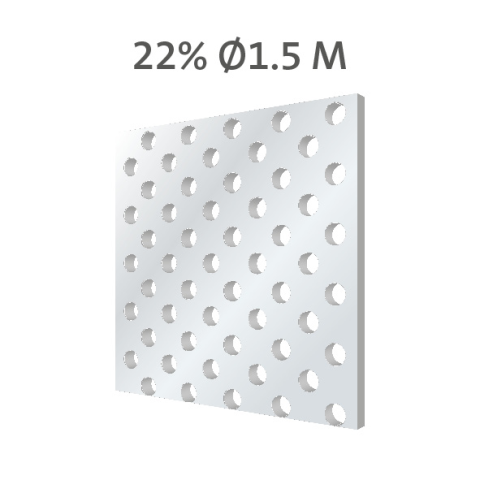

- 22% Ø1.5 M

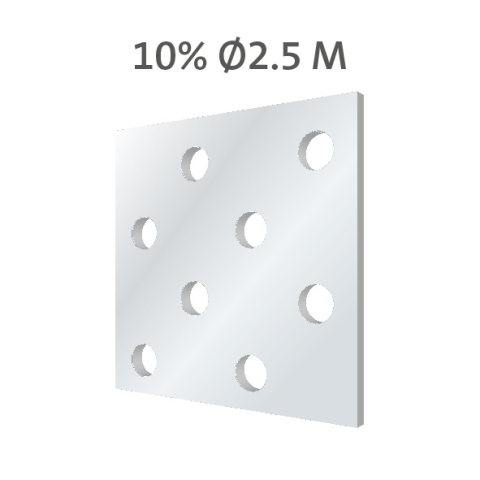

- 10% Ø2.5 M

- 12% Ø2.5 U (only with perforations that stop short on the four sides)

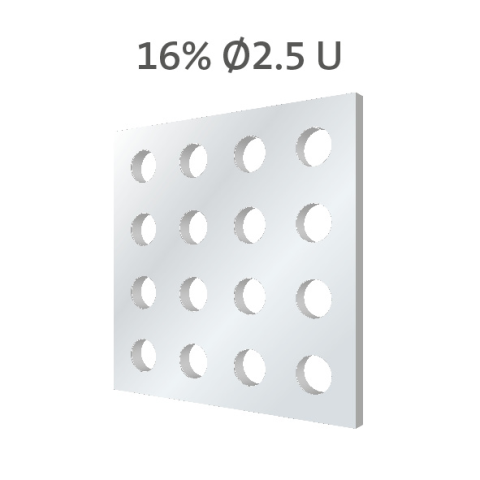

- 16% Ø2.5 U (only with perforations that stop short on the four sides)

- 23% Ø2.5 M

- 20% 61x4 U (only with perforations that stop short on the four sides)

- 40% 61x4 U (only with perforations that stop short on the four sides)

- 18% ØIRR irregular (maximum width 400 mm)

Module dimensions

- Widths: 300, 400 and 600 mm. Others available on request.

- Length on request (min. 800 – max. 2,500 mm).

- Height 35 mm.

- Max. self-supporting capacity: 2,500 mm for a width of 300 mm.

Packaging

Cut outs and integrations

- Bespoke factory cut-outs on request.

A day-to-day support

At Plafometal, we support our customers on a daily basis through each step of a construction project. Following the whole project, from the building owner’s request to the delivery, we provide our customers with all advice and recommendations they may need.